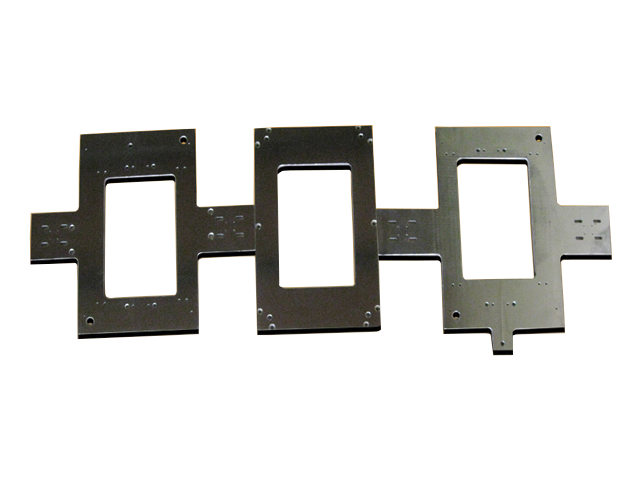

Electroless Nickel (EN) Plating

Electroless Nickel plating is a new technology of coating method which replaces Hardchrome in many areas where critical profile have to be plated. Widely used in accurate dimension controlled jobs.

Advantages of Electroless Nickel Plating

- Uniformity in all deposits, even on complex shapes, thickness variation of 0.1 micron

- Deposits are often less porous and thus provide better barrier corrosion to steel substrates, much superior to that of electroplate nickel

- Surface harness; ranging from 40 - 68 RC

Areas of Appplication of Electro Less Nickel Plating

Due to its unique properties of excellent corrosion resistance, combined with a high wear resistance and uniformity of coating, Electroless Nickel Plating finds extensive applications in a number of fields.

Some of the prominent areas of application are

Valve Components, such as Balls, Gats, Plugs, Pump Housing and Impeller, Mixing Blades, Plastic Injection Mould, Blow Moulds, Spinneret's Threaded Guides, Heat Sinks, Gears, Satellite and Rocket Components, Capsule Machinery Dies, Chocolates Moulds and food processing machinery components.